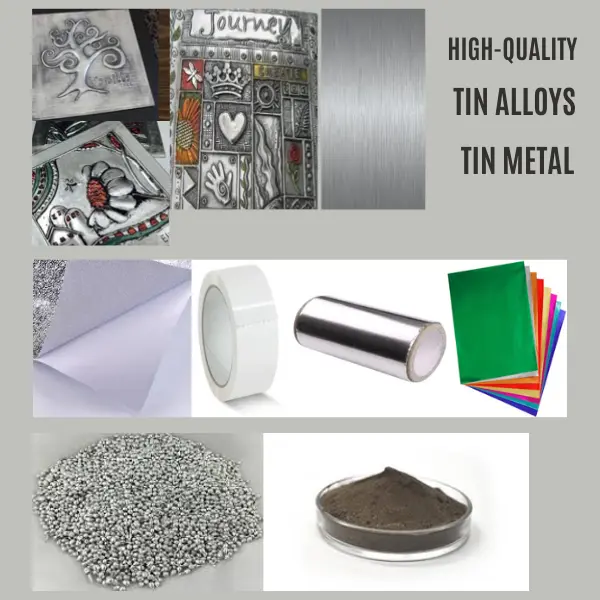

High-Quality Tin Alloys & Tin Metal

Trusted Manufacturer & Supplier in India

At Jaytee Alloys & Components Limited, we specialize in manufacturing and supplying high-quality tin metal and a wide range of tin-based alloys tailored to the dynamic demands of modern industries. With more than a decade of metallurgical experience, cutting-edge infrastructure, and certifications like ISO 9001:2015 and ISO 14001:2015, we are your go-to partner for all things tin.

Our tin products are trusted across the globe for their purity, performance, and adaptability. Whether you need tin for soldering applications, electroplating, or specialty alloys, our high-purity (99.99%+) materials are engineered to deliver consistent results every time.

Wide Range of Tin Products We Offer

As a trusted tin metal distributor and supplier in India, Jaytee Alloys offers a broad spectrum of tin products to cater to a variety of commercial and industrial applications. So, if you're in need of base materials for manufacturing, alloying agents for high-performance engineering, or refined forms for research and development, we have you covered.

We offer tin in a wide variety of shapes and forms, customized to suit both commercial and industrial applications:

Tin Shots

Perfect for alloying and precision casting, these spherical tin particles offer high surface area and consistent size distribution.

Tin Granules

Ideal for industrial mixing and casting, our granules ensure homogeneous distribution in alloy matrices.

Tin Powder

Used in electronics, 3D printing, and advanced metallurgy, our high-purity tin powder provides excellent flow characteristics and uniformity.

Tin Oxide

Utilized in polishing, ceramics, and chemical industries, tin oxide offers excellent thermal stability and catalytic efficiency.

Tin Anode

Essential for electroplating applications, our tin anodes ensure smooth coatings with superior corrosion resistance.

Tin Ingot

Refined ingots suited for melting, casting, and custom alloy production with guaranteed 99.99% purity.

Tin Sheet

Versatile and corrosion-resistant, tin sheets are ideal for shielding, roofing, and chemical processing.

Tin Wire

Available in multiple gauges, used for soldering and electronic connections with optimal conductivity.

Tin-Zinc Wire

A specialized alloy used in aerospace and automotive industries for anti-corrosion coatings and thermal spraying.

Tin Stick & Tin Bar

Used in soldering and industrial welding applications where precision and purity are paramount.

Applications of Tin and Tin Alloys that We Manufacture & Supply

Tin metal and its diverse alloys are vital across industries due to their unique properties such as corrosion resistance, malleability, high purity, and excellent conductivity. As a leading tin metal and tin alloy manufacturer in India, Jaytee Alloys provides tailor-made tin solutions that help improve performance, longevity, and environmental compliance.

- Electronics & Soldering: Our tin powder, wire, and bars play a vital role in lead-free soldering, offering excellent wetting, low melting points, and high electrical conductivity — ideal for printed circuit boards and microelectronics.

- Electroplating: Jaytee’s high-purity tin anodes are used extensively in industrial and consumer goods plating to create corrosion-resistant and aesthetically pleasing finishes.

- Chemical Industry: Our tin oxide and granules act as essential catalysts in chemical processes and are widely applied in pigment, glass, and ceramic production.

- Aerospace & Automotive: Tin-zinc wire and tin bars from Jaytee Alloys are used in thermal spray coatings to protect metal surfaces from heat and corrosion, extending the life of components in demanding environments.

- 3D Printing & Metallurgy: Our high-purity tin powder is formulated to support additive manufacturing, enabling precise, layer-by-layer construction of metal parts with improved metallurgical properties.

Our products help reduce production errors, improve yield, and ensure that your end products meet global industry standards.

Why Choose Jaytee Alloys for Tin Products?

As a leading tin metal manufacturer and supplier in India, Jaytee Alloys combines quality, scale, and service to support industries globally. Our commitment to delivering high-purity tin alloys in diverse forms makes us a preferred partner for businesses across sectors.

- Industry-Leading Quality: 99.99%+ purity ensured through advanced refining processes.

- Customization & Flexibility: Tin products available in custom sizes, packaging, and compositions.

- Bulk Supply Capability: Reliable partner for high-volume orders with consistent delivery.

- Environmentally Responsible: Compliance with RoHS, ISO, and eco-friendly manufacturing standards.

- Technical Expertise: Backed by decades of experience and metallurgical knowledge.

Partner with India’s Leading Tin Metal Manufacturer – Jaytee Alloys

If you’re looking for a trusted tin metal manufacturer, supplier, and distributor in India, Jaytee Alloys is your reliable partner, offering superior-quality tin products designed to enhance your production efficiency, reduce downtime, and maintain consistent product quality. If you’re in need of buying bulk supply or custom solutions, our team is here to support your requirements with unmatched service and expertise.

To get started, request a quote or learn more about our offerings by contacting us today.

Our Certifications